Skip to content

Research Areas

-

Nanocomposite Materials and Tribochemistry

-

Physical and Electrical Properties of Polymers

-

Triboelectricity

-

Tribology (Lubrication and Friction)

-

Surface Chemistry

-

Nanomaterials

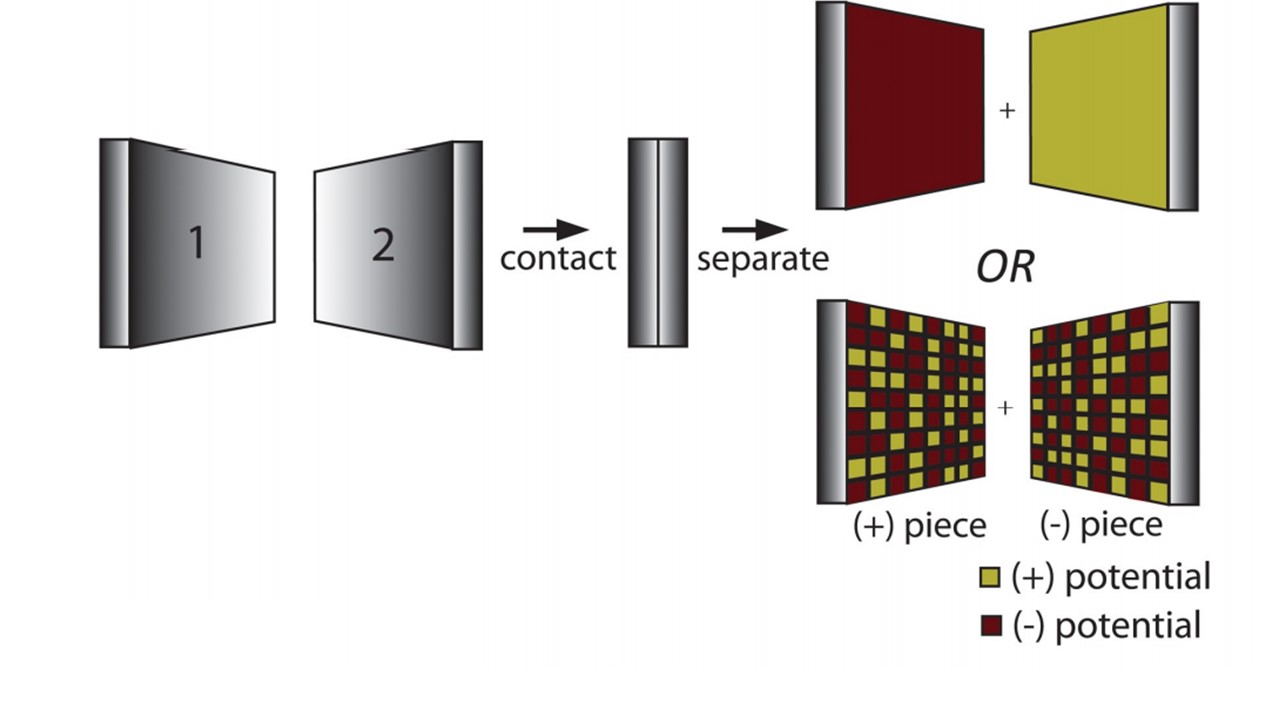

Our research group works on electrical, physical, and chemical changes that occur when surfaces get into physical contact, or when materials are used, like oxidation of lubricants in an engine. Upon contact between materials (e.g. a common tribological event), many physical and chemical changes takes place on their surfaces. Triboelectricity (frictional electricity) produces static electrification, a source for electrical energy for e.g. low-powered electronics.

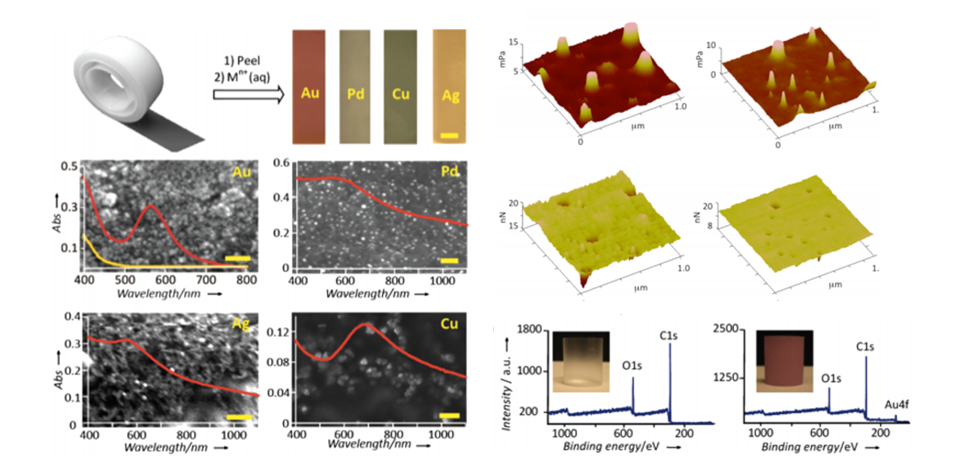

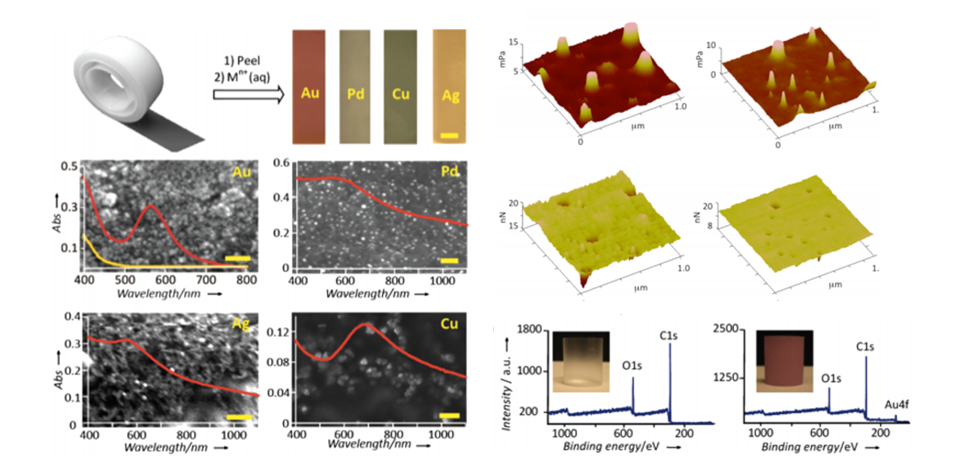

We study surface chemistry, examine, analyze and modify surfaces at molecular and nano level to tailor their properties for applications in the various technologies e.g. electronics, MEMS, air-space, and polymer manufacturing. We aim to prolong the lifetime of liquid lubricants (oils) using nanomaterials e.g metal nanoparticles.

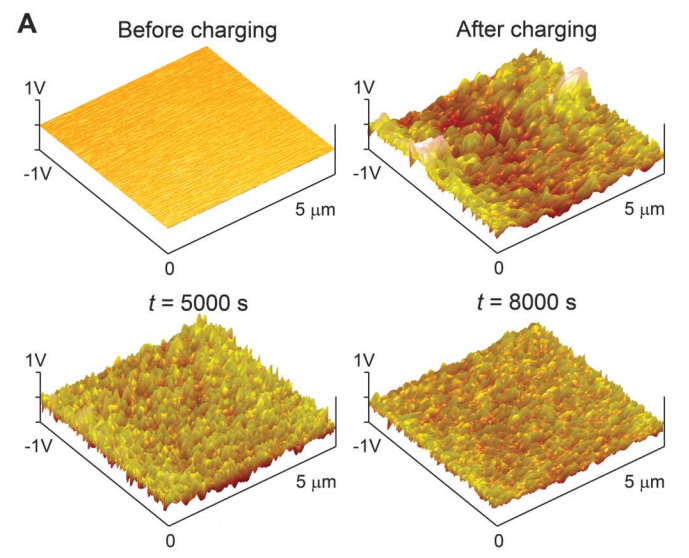

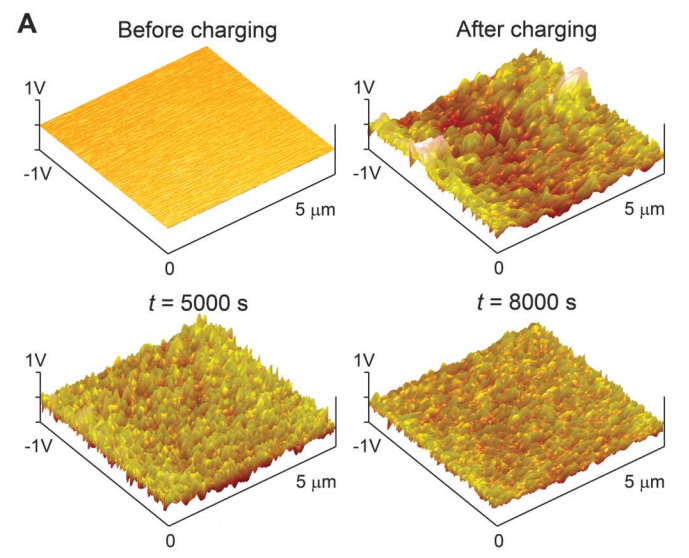

Triboelectricity of Polymers

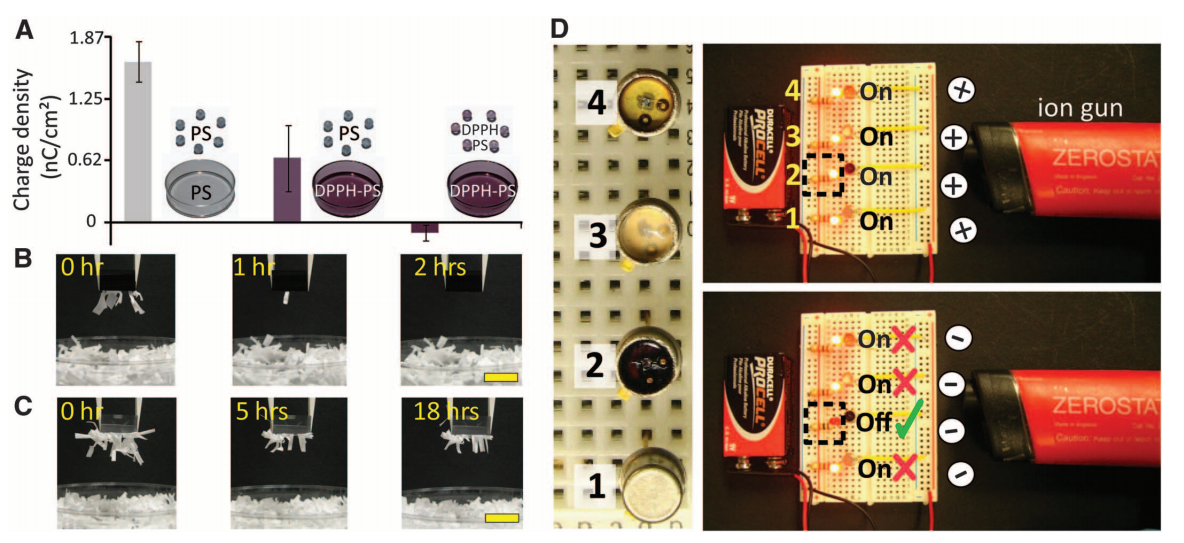

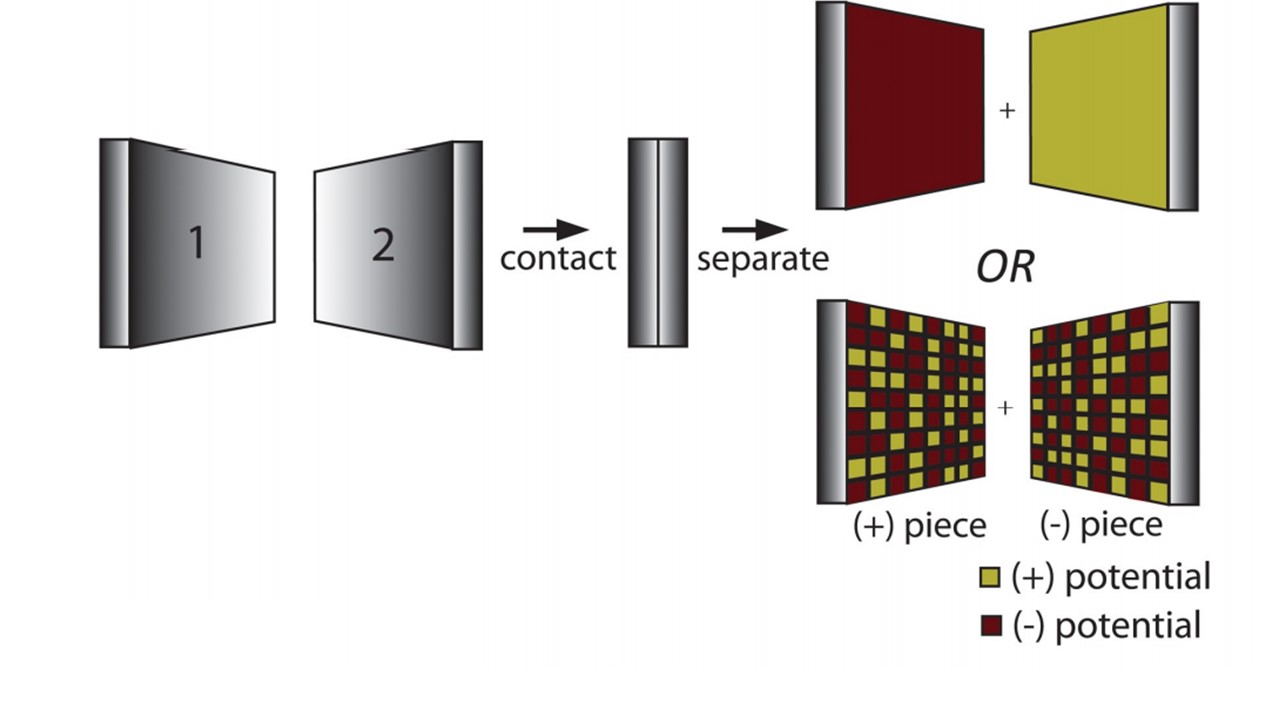

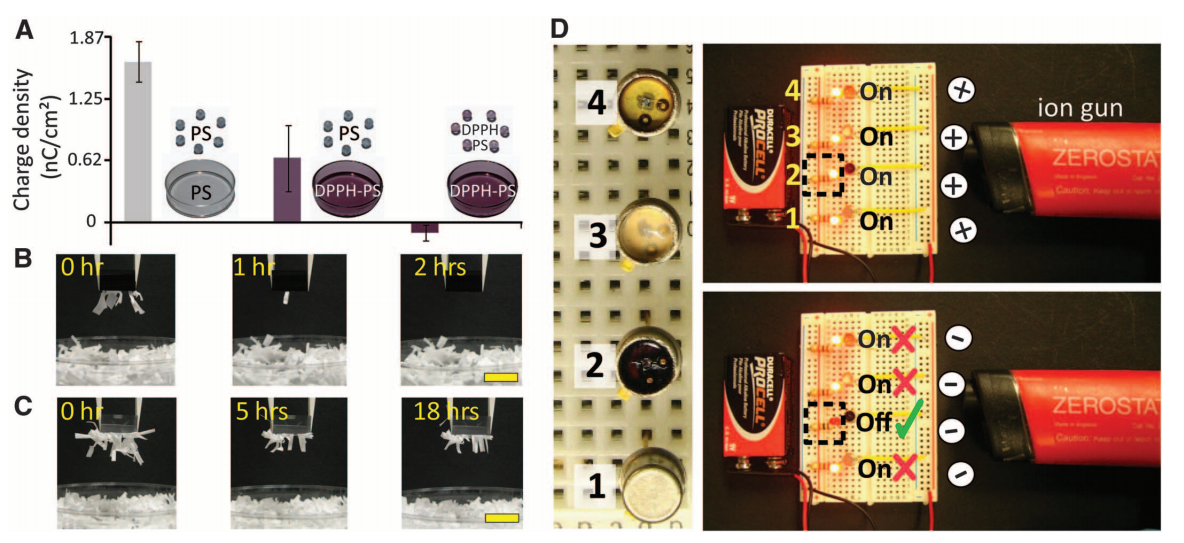

Polymers are the most encountered materials in our everyday life with a rapid growth of utilization. The versatility of the uses of polymers, from spacecrafts to ordinary plastic bags, the variety of chemical and physical properties and their dependence on environmental conditions hinder a better understanding of the electrical behavior of the (dielectric) polymer surfaces. Nevertheless, we have recently shown that it is possible to build a systematical understanding of electrical properties of polymers, especially on their electrostatics, and to find a way to control electrification successfully.

It is a millennia-old problem to understand the electrification of insulators. Our group contributes largely in finding out solutions for this question on the fundamental basis. Moreover, we develop new methods based on this knowledge to mitigate polymer electrification. These methods can be useful in many technologies, where polymers get into play, such as textile, plastic manufacturing, air and space industries.

Nanocomposite Materials and Tribochemistry

On every contacting surface chemical changes take place, depending on the nature of contact. These changes cause many problems and economical loses in industry e.g. in automotive industry. In our group, we also work on preventing these losses and to increase efficiency of work done by such surfaces.

“Revealing physical and chemical changes on the surfaces at the molecular level help us to find solutions to the problems such as static electricity, friction and wear”

Antistatic Materials

Electrostatic discharge (ESD) failure is one of the most common sources of permanent failure of electronic devices. However, currently there exist no charge dissipative antistatic conformal coating materials which would help prevention of such a devastating damage. In principle, some known/common antistatic additives could be added or blended with conformal coating materials, however they are not appropriate for this purpose because all common antistatic additives dissipate charges on a charged surface by increasing its surface conductivity; either indirectly by increasing the relative humidity on the surface by attracting water molecules to form a continuous layer on it (e.g. ionic additives), or by their inherent conductivity (e.g. metals, conductive polymers).. Therefore, non-conductive antistatic coating is necessary to protect electronics from ESD or charge accumulation.